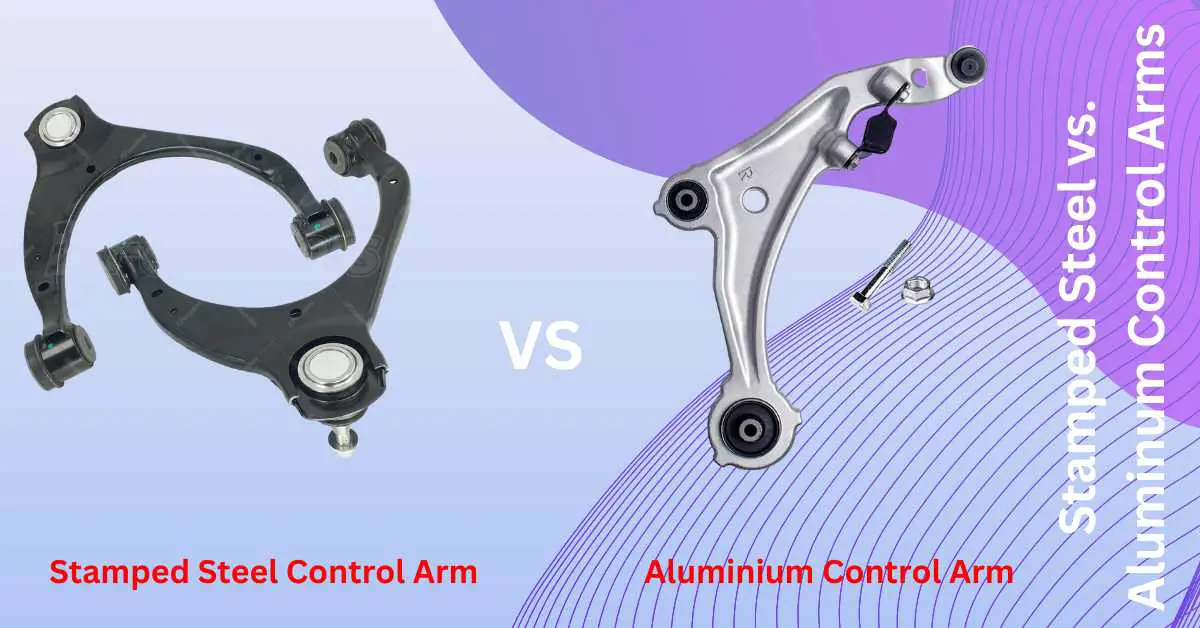

Control arms, or A-arms, are crucial to a vehicle’s suspension system. They serve as connection points between the front wheel assemblies and the car frame. Thus, they allow the driver to steer the car while guiding the wheels up and down on the road surface. In this blog, I will discuss stamped steel vs. aluminum control arms.

Control arms are made of either stamped steel, cast iron, or cast aluminum. Stamped steel control arms are made from sheets of steel that are cut and shaped. Alternatively, manufacturers use lightweight aluminum to make aluminum control arms.

Control arms ensure your tires stay in contact with the road to stabilize the vehicle. They reduce friction and vibration when steering, providing a smooth and comfortable driving experience. However, I suggest you read the whole blog to know more about these two control arms.

Brief Overview of Stamped Steel vs. Aluminum Control Arms

Here’s a comparison table highlighting the differences between stamped steel and aluminum control arms:

| Feature | Stamped Steel Control Arms | Aluminum Control Arms |

|---|---|---|

| Weight | Heavier | Lighter |

| Strength | Adequate | High |

| Rigidity | Less rigid | More rigid |

| Corrosion Resistance | Susceptible to corrosion | Resistant to corrosion |

| Manufacturing Process | Stamping and welding | Casting and machining |

| Impact on Ride Comfort | Slightly reduced | Improved |

| Design Flexibility | Lower | Higher |

| Heat Dissipation | Poor | Excellent |

| Cost | Lower | Higher |

| Aesthetic Appeal | Less visually appealing | More visually appealing |

| Fatigue and Stress Fracture | Lower | Higher |

| Performance (Racing) | Limited performance benefit | Improved performance |

Stamped Steel Control Arms: Definition, Advantages, & Disadvantages

Stamped steel control arms are made from sheets of steel. These sheets are cut and shaped to form the control arm. However, these control arms are a common choice for many vehicles primarily for their cost and availability.

The primary material used for stamped steel control arms is, of course, steel. The automotive industry has used this material for its strength and durability for many years. Hence, manufacturing involves cutting and shaping steel sheets into the desired shape.

Manufacturers use a stamping machine to apply pressure to the steel sheet. Then, they create the control arm’s shape using the sheet. The parts are then welded together to form the final control arm structure. This process allows for large production runs and relatively low production costs.

Advantages of Stamped Steel Control Arms

Stamped steel control arms offer several benefits to a vehicle’s suspension system. Some of these advantages include:

- Affordability: Stamped steel control arms are generally cheaper than aluminum control arms. So, they are a popular choice for most vehicle manufacturers (mzwmotor).

- Ease of Manufacturing: The manufacturing process of stamped steel control arms is relatively simple. It makes them suitable for high-volume vehicle production.

- Replaceable Ball Joints: Stamped steel control arms often have bolted-in ball joints. These joints make them easily replaceable when worn or damaged. It can be an advantage for maintenance and repair (silveradosierra).

- Durability: Steel is a strong and durable material. So, stamped steel control arms provide reliable performance and longevity in the suspension system.

Disadvantages of Stamped Steel Control Arms

Besides advantages, some drawbacks are there to using stamped steel control arms in a vehicle’s suspension system:

- Weight: These control arms are typically heavier than their aluminum counterparts. It can lead to increased weight in the suspension system. Also, it can potentially impact fuel efficiency.

- Susceptibility to Rust: Stamped steel control arms are more prone to rust and corrosion when exposed to damp environments and road salt. It reduces lifespan and increases the need for replacement.

- Limited Stiffness: According to a forum thread, these control arms may offer less stiffness than forged or cast control arms. It can affect handling and ride quality.

- Ball Joint Failure: Some control arms have a ball joint design with a smaller surface area for retention and no supporting clips. It can cause ball joint failure if the cup becomes distorted.

Aluminum Control Arms: Definition, Advantages, & Disadvantages

Aluminum control arms are an alternative to stamped steel control arms in a vehicle’s suspension system. They are usually used due to their lightweight properties. Likewise, it can improve handling and reduce overall vehicle weight.

The primary material for these control arms is aluminum. This metal is extracted from bauxite ore. Thus, aluminum is chosen for its strength, flexibility, and lightweight properties. In some cases, manufacturers may use other metals or materials to enhance the efficiency of aluminum control arms.

You can find aluminum control arms in various vehicle models. Notably, most manufacturers use them in the latest performance-oriented or premium cars.

The aluminum control arms production typically involves two main processes: the Bayer process and the Hall-Heroult process.

- Refining the bauxite ore to get aluminum oxide (Al₂O₃) through the Bayer process (ScienceDirect).

- Smelting the aluminum oxide (Al₂O₃) to release pure aluminum using the Hall-Heroult process (madehow).

The pure aluminum is then cast into molds, cooled, and finished in the desired shape for the control arm.

Advantages of Aluminum Control Arms

Aluminum control arms offer several benefits compared to their stamped steel counterparts:

- Lightweight: Aluminum control arms are generally lighter than stamped steel control arms. It reduces the overall vehicle weight and improves handling.

- Corrosion Resistance: These control arms are more corrosion-resistant than stamped steel control arms. So they will last longer without getting rusty.

- Strength: Aluminum control arms provide increased power than stamped steel control arms. They do not break down at low temperatures and maintain their toughness.

- Improved Design Flexibility: These things offer greater design flexibility. So, you can get enhanced suspension performance as manufacturers can create more complex and intricate shapes.

- Fuel Efficiency: The lighter weight can improve fuel efficiency in vehicles. They need less energy to accelerate and maintain speed.

- Resilient and Lightweight: Aluminum control arms are more robust and lighter for their hexagonal crystal structure.

Disadvantages of Aluminum Control Arms

You may get some negative impacts from using aluminum control arms. Some of them are:

- Cost: Aluminum control arms can be more expensive than stamped steel for the higher cost of aluminum as a raw material. It also involves the complexity of the manufacturing process.

- Potential for Fatigue and Stress Fractures: Aluminum control arms may be more prone to fatigue and stress fractures than steel control arms. Significantly, the chance increases under repeated or high-stress loads as aluminum generally has a lower fatigue limit than steel. Also, repeated stress cycles can eventually lead to crack propagation and failure.

- More Prone to Damage: According to RS25, aluminum is a softer material than steel. So, these control arms may be more susceptible to damage or deformation in high-stress situations or accidents.

- Limited Repair Options: Sometimes, these things may feature unitized designs where the ball joint is integrated directly into the control arm. It can limit repair options, as replacing the ball joint needs replacing the entire control arm assembly (MevoTech).

Comparing Two Control Arms – Which One is Better for Your Car?

In this section, I will describe the key differences between these two control arms. So, you can decide upon them for your car.

Weight Differences

- Stamped Steel Control Arms are generally heavier than Aluminum Control Arms. It is because steel has a higher density compared to aluminum. So, you get a heavier component for the same volume. Using stamped steel control arms will add some weight to your car.

Performance Implications

- From a thread, I have found that aluminum Control Arms can provide better overall vehicle performance for their lighter weight. This reduction in unsprung weight provides improved handling, acceleration, and braking. Also, it offers a potential reduction in fuel consumption.

Longevity and Maintenance

- Stamped steel control arms have a longer lifespan and lower maintenance requirements than their aluminum counterparts. It is for steel’s higher resistance to fatigue and stress fractures under repeated or high-stress loads.

- Aluminum control arms may be more prone to fatigue and stress fractures, especially if subjected to high-stress situations or accidents.

- Corrosion resistance is generally higher in aluminum control arms. So, they last longer than other control arms in specific environments.

Vehicle Applications

- Older vehicles (especially full-framed cars) often used stamped steel control arms for their low cost and ease of manufacturing.

- Many modern vehicles use aluminum control arms due to their lighter weight and higher corrosion resistance. It offers these cars better fuel efficiency and performance.

Frequently Asked Questions

Can I upgrade from stamped steel to aluminum control arms?

Answer: Yes, you can. But ensure compatibility with your vehicle’s suspension system, including the size of the ball joint hole and the knuckle. You may also consult a mechanic or automotive expert to confirm compatibility and assist with the installation.

How can I determine if my control arms require replacement?

Answer: Signs that your control arms may need a replacement include:

- Clunking or rattling noises from the suspension, mainly when going over bumps or turning.

- Uneven tire wear

- Poor handling or steering response

- Visible damage to the control arm or bushings If you notice any of these symptoms, consult a professional mechanic for an inspection and diagnosis.

Is there any difference in performance between stamped steel and aluminum control arms?

Answer: Weight and corrosion resistance are the main differences. Aluminum control arms are lighter, improving performance, handling, and fuel efficiency. They also have better corrosion resistance.

Besides steel and aluminum, are there any alternative materials utilized for control arms?

Answer: Yes, carbon fiber! Cast-iron control arms are popular in trucks and SUVs due to their strength and ability to withstand harsh environments. They are better than stamped steel control arms. Also, they offer high strength-to-weight ratios and better corrosion resistance.

Conclusion

“Stamped steel vs. aluminum control arms” – the discussion concludes here. I have explained all the relevant differences between these two control arms in this blog post.

In short, if you want to save money on control arms, choose stainless steel. Otherwise, you can pick aluminum control arms for corrosion resistance and fuel efficiency. You should read the owner’s manual of your car before switching control arms between these two.

I hope you have enjoyed reading this comparison article. Thanks again!