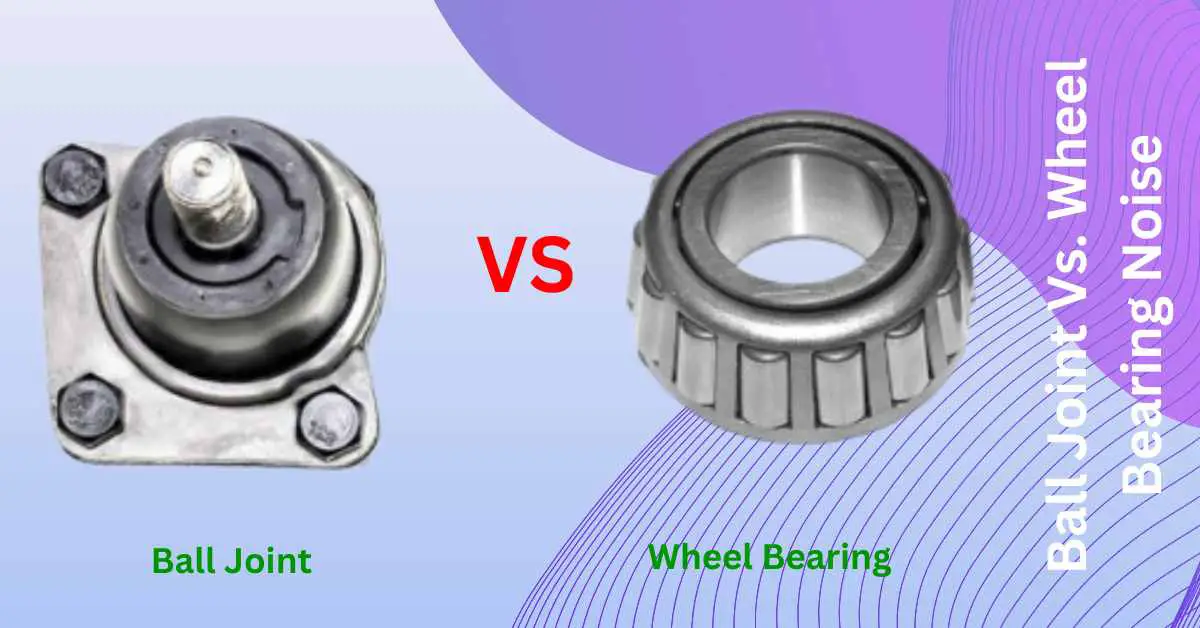

You may have heard unusual noises coming from your car. Typically, it may appear from a ball joint or wheel bearing, yet you cannot identify it. I have highlighted the debate: ball joint vs. wheel bearing noise. Throughout the article, you will learn about the nature, reason, and solutions to these noises.

A ball joint transfers force and allows the suspension system’s flexible movement. It maintains a connection between the control arm and the steering knuckle. Alternatively, a wheel bearing absorbs force and ensures smooth wheel rotation by minimizing friction between the wheel and axle. When these two components make errors, you will hear the noise.

In short, ball joint noise is like a moaning sound when turning or cornering. It indicates erosion or a lack of fluid in the ball joint. Alternatively, wheel bearing noise is often described as grinding, squealing, or humming sound. It changes following your driving speed. If you do not lubricate the bearing, you may hear this noise.

Ball Joint vs. Wheel Bearing Noise: Comparison Table

Here’s a comparison table highlighting the key differences between ball joint and wheel bearing noise:

| Aspects | Ball Joint Noise | Wheel Bearing Noise |

|---|---|---|

| Sound Nature | Metallic clunking or knocking sound | Low-pitched humming, rumbling, or growling sound |

| Occurrence | Heard during bumps, turns, or maneuvers | Constant noise, may change in intensity during turns |

| Speed Dependency | May vary with vehicle speed, load, or road conditions | Not significantly affected by vehicle speed |

| Diagnostic Approaches | Visual inspections, physical checks, movement checks | Wheel spin tests, temperature checks |

| Potential Warning Signs | Clunking or knocking sounds, abnormal tire wear patterns | Low-pitched humming or rumbling, vibration |

| Repair Approach | Replacement of worn or damaged ball joints | Replacement of worn or damaged wheel bearings |

Ball Joint & Its Noise

You can learn about ball joints, their problems, identification, and noise diagnosis in this part. All these are important to understand the ball joint noise, which differs from wheel bearing noise.

Definition and Function of Ball Joint & Its Noise

Ball joints are crucial components of a vehicle’s suspension system. They serve as pivot points between the control arms and the steering knuckles. In this way, they allow the wheels to turn and the suspension to absorb bumps and irregularities in the road.

You can get better steering control and stability if the ball joints remain fine. Also, you can articulate the wheels and adjust to changing road conditions by providing a flexible joint.

Thus, the ball joint noise refers to the sounds produced by worn or damaged ball joints in a vehicle’s suspension system. It has distinct characteristics like clunking, knocking, or creaking sounds. You may hear this noise when the suspension moves up and down, traveling on rough roads or turning. (Your Mechanic)

Identifying Ball Joint Noise

It’s time to identify the ball joint noise. According to Moog Parts, you will hear clunking or knocking sounds when driving over uneven surfaces, speed bumps, or during turns. Repaipal considers this is squeaking or creaking noise like a noisy door hinge or rocking chair.

The clunking or knocking may be more noticeable at lower speeds. They can sometimes mimic the sound of a metal-on-metal impact.

There may be accompanying sensory cues to identify the noise, like vibrations. You may feel slightly shaking or trembling when turning or driving over rough surfaces.

Diagnostic Techniques for Ball Joint Noise

Visual inspection and specialized tools are vital steps in this diagnostic process. You can start by inspecting for signs of wear, damage, or excessive play. Also, look for visual cues like loose or missing hardware, cracked rubber boots, or grease leakage around the ball joint.

In addition to visual inspection, you can use specialized tools to assess the condition of the ball joints more accurately. For example, you can use pry bars or similar tools to apply leverage and check for excessive play or movement in the ball joint. Also, you can assess the extent of wear and damage by exerting force and observing for any visible signs.

A dial indicator can also help in this case. It precisely measures the play or movement in the ball joint. So, measure the amount of play or deflection by attaching the tool to the join and applying pressure.

The Impact and Prevention of Ball Joint Noise

When you ignore ball joint noise, it may lead to:

- Further damage to the suspension system.

- Decreased vehicle stability and excessive vibration.

- Misaligned front-end alignment, causing the car to pull to the right or left and uneven tire wear.

- Potential accidents due to loss of control or joint failure.

You can prevent and repair the ball join noise in these ways:

- Regularly inspect your vehicle’s suspension system for signs of wear or damage.

- Replace compromised rubber boots and lubricate ball joints as needed.

- Consult a professional mechanic to diagnose and replace worn or damaged ball joints.

Wheel Joint & Its Noise

Like ball joint noise, I will briefly discuss wheel bearings, their problems, identification, and noise diagnosis. You will also learn how to deal with the wheel bearing noise.

Definition and Function of Wheel Bearings

Wheel bearings enable smooth and efficient wheel rotation. They help to maintain vehicle stability and ensure a comfortable and controlled driving experience. Hence, they allow the wheels to spin freely on the axle. They also transmit the vehicle’s weight and the forces encountered during driving.

Wheel bearings also reduce friction between the rotating wheel and the stationary axle. You can rotate the wheels with minimal resistance for their low-friction interfaces. Likewise, it enhances fuel efficiency and reduces wear on the bearings and the surrounding components.

However, wheel bearing noise means the sounds of worn or damaged wheel bearings in a vehicle. Repair Smith says these noises typically include rumbling, roaring, grinding, squealing, or humming. They may change per your driving speed.

Identifying Wheel Bearing Noise

Can you remember the sound of a distant airplane or train passing by? It is like a wheel-bearing noise.

A distinctive noise of failing wheel bearings is a continuous, low-pitched humming or rumbling sound. Soundproof identifies it as rhythmic chirping, squealing, or grinding sounds. They may increase or decrease with vehicle speed, especially when turning and cornering (Mechanic Base)

You may hear the noise if you do not grease the bearing regularly. Over time, the bearings lose grease due to leakage or contamination. Again, the damaged wheel bearing components like balls, rollers, or races also cause the noises.

Diagnostic Techniques for Wheel Bearing Noise

With several methods and tools, you can also diagnose wheel bearing noise, like ball joint noise.

You can start with a visual inspection of all wheels and bearings. Identify any visible signs of damage, like worn-out seals and missing hardware. You may also find signs of excessive heat or grease leakage.

If the visual inspection fails, you may take the vehicle for a road test to listen for the noise and assess its characteristics. In this case, you should focus on speed, turning, and braking. They can influence the intensity or pattern of the noise.

You may try jiggling each wheel back and forth vertically to check for excessive play or movement. But ensure you have safely lifted and supported the vehicle while jiggling. However, excessive play can indicate a problem with the wheel bearing.

The Impact and Prevention of Wheel Bearing Noise

I know it is quite time-consuming to find out why any noise comes from the vehicle. Also, many do not care about sorting out the issues ourselves. But we can do it with a few tools and patience. Likewise, if you ignore wheel bearing noise, it may cause:

- Further damage to the bearing, which can cause the wheel to wobble or even seize.

- Damage to other suspension and steering components due to increased stress and vibration.

- Decreased fuel efficiency and increased tire wear due to misalignment.

- Potential accidents due to loss of control or wheel failure.

To prevent and repair wheel bearing noise:

- Regularly inspect your vehicle’s wheel bearings for signs of wear or damage.

- Maintain proper tire pressure and alignment to reduce stress on the bearings.

- Consult a professional mechanic to diagnose and replace worn or damaged wheel bearings.

Comparison between Ball Joint and Wheel Bearing Noise

Ball joint noise and wheel bearing noise is distinct in their characteristics. These characteristics can help diagnose the problem’s source in a vehicle.

Location and Type of Noise

Ball joint noise is usually characterized by clunking, knocking, or creaking sounds. You can hear them when the suspension moves or during turns. In contrast, wheel bearing noise typically includes rumbling, roaring, grinding, squealing, or humming sounds. The intensity of these noises may change with driving speed.

Noise Behavior

Ball joint noise is more likely to be heard when driving over uneven surfaces or during turns. Conversely, wheel bearing noise tends to increase or decrease with vehicle speed. It may become louder when turning or cornering.

Affected Wheel Behavior

A worn or damaged ball joint can cause the suspension to move erratically. It leads to clunking or knocking sounds. A bad wheel bearing may cause the affected wheel to wobble or shake.

Frequently Asked Questions

- Can I continue driving with a ball joint or wheel-bearing noise?

- Driving with a ball joint or wheel bearing noise is not recommended for an extended period. Neglecting these problems can cause additional harm, compromised control over the vehicle, and potential risks to safety.

- Can I diagnose ball joint or wheel bearing issues myself?

- You can do some visual inspections and basic checks. But mechanics are great at diagnosing ball joint or wheel bearing issues accurately with their specialized knowledge and tools.

- What is the average cost of replacing a ball joint or wheel bearing?

- The average cost to fix the wheel bearings is about $300-350 for one wheel. On the other hand, ball joint replacement is within $20-80 on average.

Conclusion

Now, the discussion of ball joint vs. wheel bearing noise ends here! You should diagnose and address the noises to ensure the optimal functioning of a vehicle’s suspension system and wheel assembly. In this blog, I have thoroughly explained the nature, reasons, and solutions to these noises.

Identify whether it is from a ball joint or wheel bearing. Then, treat the problems accurately by yourself or call the assistance of mechanics. I hope you have understood my explanation regarding them.

I appreciate you for reading till now.