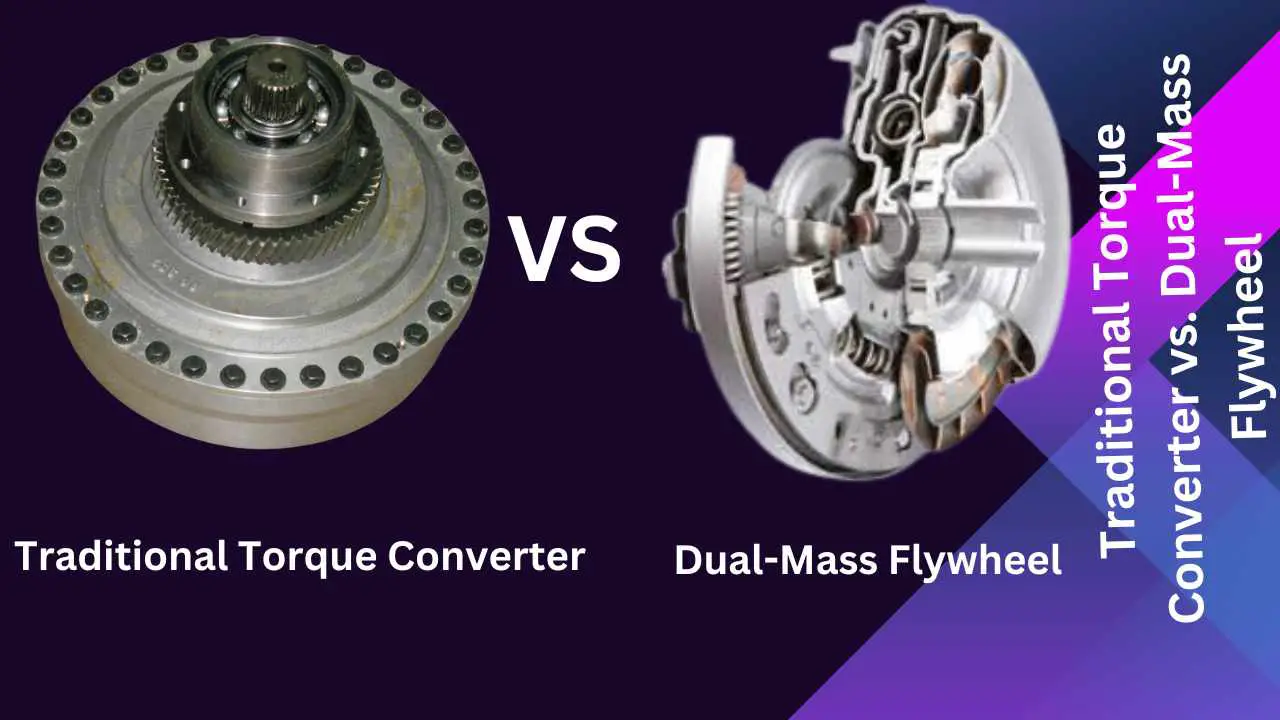

Often, we find things complex to understand easily. For example, the torque converter and dual-mass flywheel – are two essential components of a vehicle’s transmission system. They transfer engine power to the drivetrain to move our car forward. However, many of us know very little about them. So, I have decided to discuss traditional torque converter vs. dual-mass flywheel in this blog.

Well, a torque converter transfers power from the engine to the transmission input shaft. It can almost double the output torque (1). Also, it isolates the engine from the load when the vehicle is stationary (2). On the other hand, you can fit a dual-mass flywheel into cars with a manual gearbox. It protects the driveline from the engine’s torsional vibrations (3).

For sure, that was just a glimpse! Once you read the whole post, you will learn more about these key components. More precisely, I will focus on their functions, pros, cons, and valuable ideas. So, please spend some time here, and I promise your time will not go in vain!

Traditional Torque Converter: Functions, Applications, Pros, Cons, & Maintenance Cost

Every time I am up to something, I try to research well to write about them. For today’s topic, I have done the same thing. Likewise, according to some sources (4,5,6), I have found this information about traditional torque converters.

Functions

What is a traditional torque converter? It transfers rotating power from a main to a rotating driven load. Usually, we use it as a fluid coupling in an automatic transmission. You can find this converter between the engine’s flexplate and the transmission system.

A converter increases the transmitted torque when the output rotational speed is low. It has three stages of operation: stall, acceleration, and coupling. Impeller, turbine, and stator- these three things are core components of a torque converter. In an automatic transmission –

- The impeller is joined to the engine and spins with it.

- Then, the turbine is connected to the transmission.

- The stator rests between the impeller and the turbine. It redirects fluid from the turbine back to the impeller. As a result, the drivetrain gets multiplied by torque.

The converter allows the engine to spin somewhat independently of the transmission. Well, this independence is essential. How? It enables the engine to continue running even when the wheels halt. Through this, the converter prevents the engine from stalling.

Applications

If your car has an automatic transmission system, it must have a traditional torque converter. Indeed, it works as a replacement for the mechanical clutch (7). It is also used in hybrid vehicles as it can provide smooth gear shifting and improve fuel efficiency (8). Additionally, you can customize this converter to be compatible with different systems.

Pros

You can find several benefits of using traditional torque converters. Some are less noise, less wear on transmission components, and smooth clutch engagement. Also, they do not need human action for the system to operate (9).

A great advantage of a torque converter is its allowance for the engine to keep running even when the vehicle comes to a stop. So your truck or car won’t stall in the middle of the road. And I guess we all know how it feels to have a car stalling in heavy traffic or urban driving conditions.

Another benefit is it can enhance car’s performance by increasing its engine’s torque during acceleration from a stop. Your vehicle gets smoother and quicker acceleration to make your trip more enjoyable.

Cons

Unfortunately, using traditional torque converters has some disadvantages. For example, they can be less fuel-efficient than comparable manual cars. Also, they cannot match a twin-clutch transmission for shifting speed (10).

A torque converter is generally less efficient than a manual transmission with a dual-mass flywheel. Also, the fluid coupling can cause a certain amount of power loss and reduced fuel efficiency (11). Sometimes they may overheat and wear, mainly if you drive the vehicle under heavy load or use it for towing.

Maintenance Cost

Autozone sells automatic transmission torque converters at $63.99, the lowest price. It may even go up to $1191 as the highest price. Then again, a torque converter for a 7.3 model from Ford is priced around $1800 (found in a forum).

Dual-Mass Flywheel: Functions, Applications, Pros, Cons, & Maintenance

As I said, I do research – I will add some references in this section. In this part, I will explain how dual-mass flywheel (DMF) works, its applications, and its positive and negative sides.

Functions

What is a dual-mass flywheel? Have you heard about it? Well, a DMF is a rotating mechanical device. It protects the driveline of a vehicle from the torsional vibrations of the engine. More specifically, you can find it in cars and trucks with manual gearboxes (3).

DMF has two parts separated by various means, often springs that connect primary and secondary flywheels. These springs allow the two halves to move or rotate independently within a limited range. However, this structure or functionality differs from conventional flywheels made from a single piece of metal (12).

The dual-mass flywheel design helps dampen any violent variation of torque or revolutions. In this way, DMF reduces unwanted vibration and provides continuous rotational energy even when the energy source is inconsistent (13).

According to AMS Automotive, the primary functions of dual-mass flywheel are:

- Storing energy from each piston’s firing pulse

- Dampening damaging torsional spikes caused by engine vibration.

Applications

DMFs provide continuous energy in systems where the energy source is not constant. They dampen any extreme torque changes that could cause unwanted vibration.

Well, the purpose of developing DMFs was to address the escalation of torque and power (specifically at low revs). It was done by lowering the cylinder number to 3 or even two cylinders.

Pros

The most notable benefits include smoother clutch operation, improved gear shifts, and an overall reduction in vibration throughout the vehicle. Some applications may even see a marginal increase in fuel economy (12). Mainly, DMF is beneficial for high-torque, fast-spinning motors. It manages the vibrations these engines produce.

You can get more advantages of a dual-mass flywheel if you have first-class passenger cars and light commercial vehicles. The DMF reduces driveline and body noise in these vehicles to provide smoother travel with more friendly gear shifts (14).

Another benefit of the dual-mass flywheel is getting extra facility when replacing a clutch. Let me make it clear. You can get versatile replacement options, from a direct replacement of the DMF style clutch to a single disc with a solid flywheel. You may even use a solid flywheel with dual disc (15).

DMF’s role in protecting the gearbox from potential damage for high torque levels is another advantage. So, you can consider it a valuable component in modern vehicles, mainly vehicles with powerful engines to generate high torque levels.

Cons

You should also consider the critical aspects of using a dual-mass flywheel. For instance, a DMF’s major downside is the expense and reliability trade-off. It is usually more costly and less durable than single-mass flywheels (16). Moreover, you may need to spend more due to its complex design and the precision required in its manufacturing.

Also, dual-mass flywheels are prone to wear and degradation over time. If you often drive aggressively under harsh conditions, you may need to replace DMFs soon. Besides, the wear may cause juddering on take-off or increased noise and vibrations.

Maintenance Cost

The average replacement cost for a DMF in the UK is around £750-£1,500. With material costs, it can range from £400-£1,200 (17). Single-mass flywheels are another option, which is simpler and cheaper than DMFs. However, they may have more noise, vibration, and harshness during operation (18).

Final Words: Traditional Torque Converter vs. Dual-Mass Flywheel

I am at the end of the conversation! Let me recap the whole thing.

Dual mass flywheels (DMFs) and traditional torque converters serve similar vehicle functions. Still, they have some differences. DMFs can protect the driveline from the engine’s torque pulses and torsional vibrations.

Alternatively, a torque converter keeps the engine running and prevents it from stalling. It works as a fluid coupling in an automatic transmission.

However, you can find conversation kits for transitioning from traditional torque converters to dual-mass flywheels. For example, Dodge Cummins Solid Flywheel Conversion Kits are suitable for certain Dodge Ram pickups with a Cummins Diesel and a Mercedes G56 transmission (19). Still interested? You can search Google for conversions about these things.

I hope you have understood what I discussed in this blog. If you loved it, please comment in the comment section.

Have a nice day!