We all know that internal combustion engines are the heart of countless vehicles. The spark plug is a small yet critical component (or insulator) that lies at the core of these engines. Hence, it plays a vital role in igniting the air-fuel mixture within the combustion chamber. But all these spark plugs are not created equally. You can find them in two types: projected and non-projected spark plugs.

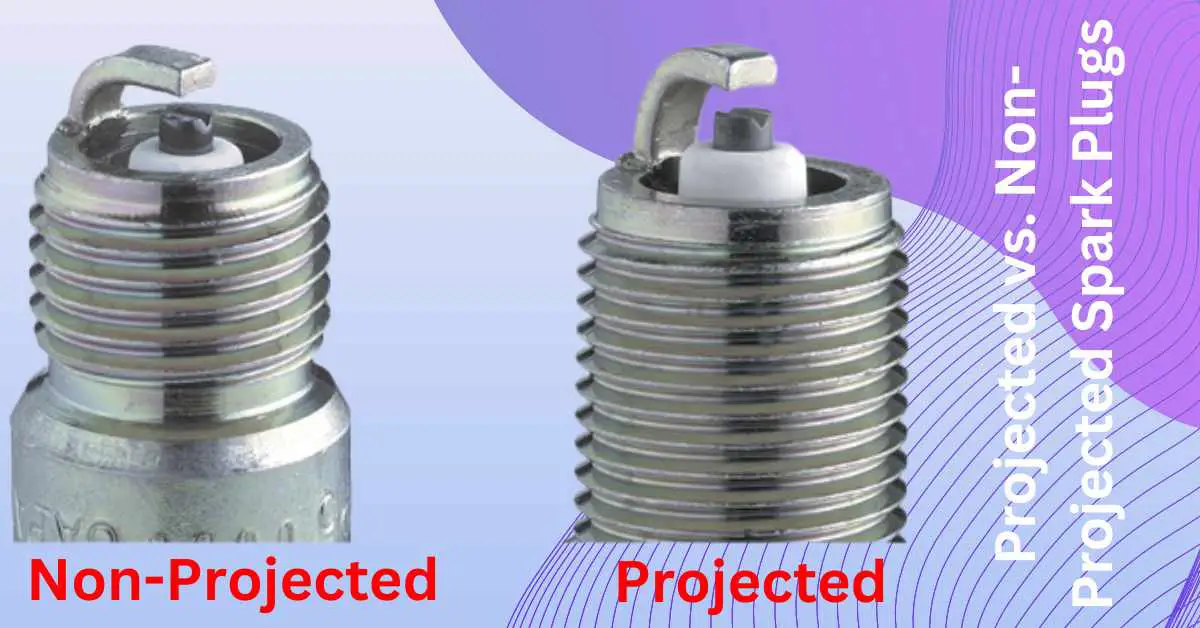

A projected version extends beyond the metal shell of the spark plug. It has a protruding electrode tip to posit the spark closer to the center of the combustion chamber. Alternatively, the non-projected spark plug does not extend beyond its metal shell. It has a flush or flat design where the electrode tip is aligned with the metal shell.

These two components or spark plug insulators impact an engine’s performance, fuel efficiency, and overall driving experience. After reading, you will understand which spark plug will be most suitable for your machine. So, it is time to ignite your curiosity and unleash the full potential of your engine!

A Brief Overview of Spark Plug Design

When you read about spark plugs, you will find some technical words or phrases you should know first. In this part, I will discuss these things.

Anatomy of Spark Plugs

Shell

What you see from the outside (housing) is the shell. It provides structural integrity and a connection point for installation and removal.

Insulator

The ceramic insulator separates the center electrode from the shell. It ensures electrical insulation and effective heat dissipation.

Center Electrode

The center electrode extends into the combustion chamber at the spark plug’s center. It delivers an electrical spark to ignite the air-fuel mixture.

Ground Electrode

The ground electrode lies opposite the center electrode. It provides a surface for the electrical spark to jump across to complete the circuit.

Gap

The gap means the space between the center and ground electrodes. An electrical spark occurs within this gap that ignites the compressed air-fuel mixture.

Electrode Types and Configurations

Spark plugs come in various electrode types and configurations, each with unique characteristics. The most common electrode types include copper, platinum, and iridium.

Copper electrodes are good for high-performance applications. Platinum electrodes are suitable for engines with extended service intervals. Again, the iridium electrodes are excellent for enhanced spark concentrations and ignitability.

Heat Range and Its Impact on Performance

The heat range of a spark plug refers to its ability to dissipate heat generated during combustion. It depends on the insulator design, electrode materials, and overall construction.

The right heat range of an engine ensures proper spark plug performance. For instance,high-performance or forced induction setups require spark plugs with a colder heat range. It will manage the increased heat generated effectively. Alternatively, engines operating under normal conditions may benefit from spark plugs with a hotter heat range. It may prevent fouling and deposits during ignition.

The Concept of Projection

“Projection” refers to extending the center electrode beyond the insulator tip. It projects the electrode further into the combustion chamber.

How Projection Works

Projected spark plugs are designed with a center electrode. It extends beyond the insulator tip, closer to the combustion chamber. This extension alters the position and reach of the spark within the cylinder during the ignition process.

In contrast, non-projected spark plugs have a center electrode. It ends at or is slightly recessed from the insulator tip.

Projected Spark Plugs: Performance and Benefits

Projected spark plugs have a unique design. It extends the center electrode beyond the insulator tip.

According to NGK, these plugs “produces a spark in the middle of the circle allowing for an even flame spread.”

Thus, this design offers several performance advantages and benefits. Some of these advantages are:

Improved Ignition Efficiency

Projected spark plugs offer better ignition efficiency. They project the spark closer to the center of the combustion chamber or the air-fuel mixture. In this way, these spark plugs create a more concentrated spark and enhance flame kernel growth. Also, this process leads to faster and more complete combustion.

Better Power Output

This optimized combustion of projected spark plugs increases power output and improves engine performance. So, the vehicle or machine gets better acceleration and overall responsiveness.

Reduced Risk of Detonation

Detonation or engine knock is a significant problem in any combustion engine. It occurs when the air-fuel mixture ignites unevenly or prematurely. But if the engine features a projected spark plug, it may mitigate the risk of detonation. Besides, it provides a more focused and reliable ignition source. This is why high-performance engines have this type of spark plug.

Reduced Fouling and Carbon Buildup

When you install the projected spark plug, it will generate less carbon buildup. Even the rate of generation is comparatively lower than non-projected spark plugs. Therefore, less carbon buildup reduces the risk of engine misfires, hesitation, and poor performance. The extended center electrode design also allows for better self-cleaning. So you will need less maintenance of it.

“Projected plugs are less likely to foul because the outer threaded case doesn’t mask the center electrode and can more easily rid itself of combustion byproducts.” (Source: AccessNorton)

Extended Life

The longer electrode tip of the projected spark plug reduces electrode wear. Through this, the plug ensures consistent spark performance over an extended period. So, you will not need any frequent replacement of the spark plug.

Ideal for High-Performance Engines

High-performance engines need efficient combustion and reliable ignition. Commonly, these engines have projected versions of spark plugs as they can handle increased heat and pressure. They are also better for engines with forced induction, turbocharging, or aggressive modifications.

Non-Projected Spark Plugs: Performance and Benefits

Summitracing describes the core feature of non-projected spark plugs: “Tip of the central electrode is inside or level with the end of the threaded shell.” In these types of spark plugs, the flame does not spread evenly.

Like projected spark plugs, these non-projected types are also efficient in some ways. Below are some main features and advantages of these spark plugs:

Versatility

Non-projected spark plugs are versatile. You can use them in various engine applications. Also, these components are suitable for both gasoline and diesel engines.

Compatibility with Low to Medium Compression Engines

These spark plugs are primarily used in engines with low to medium compression ratios. Usually they are often employed in standard passenger vehicles, motorcycles, trucks, and small engines. They provide reliable ignition for engines without any requirement foradvanced combustion characteristics.

Precise Ignition Control

Non-projected spark plugs provide precise ignition control. It is because the center electrode ends at or is slightly recessed from the insulator tip. Likewise, this configuration helps create a consistent and predictable spark path. It ensures reliable ignition under different operating conditions.

Efficient Heat Dissipation

Non-projected insulators offer improved heat dissipation compared to projected insulators. The shorter center electrode reduces the thermal load on the spark plug. So, it prevents excessive heat buildup and contributes to the overall cooling of the combustion chamber. Engines operated at lower temperatures or with prolonged idling conditions have these spark plugs.

Ease of Installation

You can easily install and remove the non-projected spark plugs more than the projected versions. Their flush design helps in this case without any need for precise electrode alignment or protrusion adjustment.

Cost-Effective Solution

The simpler design and manufacturing process reduces their costs. So, you can consider the non-projected spark plugs a more economical engine option.

Broad Availability

You can find the non-projected spark plugs more for their broader usage than projected versions. So, you can source them readily and install or replace them promptly.

Which One Should I Select: Projected vs. Non-Projected Spark Plugs?

So far, you have learned that there are significant differences between these two types of spark plugs. You may now have got confused to select between them. But I am here to solve the dilemma.

Some notable factors you should consider selecting the spark plug for your engine are:

Engine Specifications

The specifications of your engine play a vital role in determining the appropriate spark plug. You should consider engine size, cylinder configuration, compression ratio, and fuel type. Different engines with different compression ratios may require spark plugs with varying heat ranges. It ensures optimal combustion and prevents premature ignition.

Ignition System

You should consider the type and capabilities of the ignition system before selecting any spark plug. For example, conventional distributor-based systems may require non-projected spark plugs. Alternatively, modern coil-on-plug setups may need projected items.

Intended Usage

Do you drive your vehicle every day? Or for towing heavy loads or pursuing high-performance applications? The intended usage can be a factor in selecting the correct spark plug. For example, you should pick projected spark plugs if your vehicle has high-performance engines for heavy workloads.

Environmental Factors

You should not ignore this factor as it (like climate, or altitude) can impact spark plug performance. For example, select plugs with specific heat ranges if you drive in extremely cold or hot temperatures. Through this, you can ensure proper ignition and combustion.

Engine Modifications

When you modify the engine, like upgrading the intake/exhaust system, you should re-think about choosing spark plugs. It is because these modifications can alter combustion characteristics, heat dissipation, and overall performance requirements.

Manufacturer Recommendations

The best suggestion is to use the manufacturer-recommended spark plug for specific engines. So, follow the owner’s manual or manufacturer’s instructions. It will help you get acompatible spark plug with a perfect heat range and electrode gap.

Common Misconceptions about Projected and Non-Projected Spark Plugs

There are several misconceptions and misunderstandings surrounding projected and non-projected spark plugs.

- Projected spark plugs always provide better performance than non-projected spark plugs.

- Non-projected spark plugs are outdated.

- Only high-performance engines benefit from projected spark plugs.

- Projected spark plugs always need engine modifications.

- Only spark plugs determine engine performance.

- All spark plugs of the same type are equal.

These above misconceptions are wrong. Both spark plugs can perform better in certain conditions and provide what you need.

Frequently Asked Questions

These are some common questions regarding projected vs. non-projected spark plugs:

Question-1: Are projected spark plugs always better than non-projected spark plugs?

Answer: Not necessarily. The optimal spark plug choice depends on engine specifications, operating conditions, and performance requirements. However, projected spark plugs offer certain advantages. But non-projected spark plugs can still provide reliable performance in specific applications.

Question-2: Can I use non-projected spark plugs in high-performance engines?

Answer: Projected spark plugs are indeed most suitable for high-performance engines. Still, depending on the specific operating conditions, you may use non-projected spark plugs for such engines.

Question-3: What are the types of projected and non-projected spark plugs?

Answer: Projected spark plugs can be a standard, multi-ground electrode, split fire, surface discharge, iridium, and platinum-tipped. Alternatively, non-projected spark plugs can be standard, copper core, V-groove, nickel alloy, and long reach.

Question-4: How often should you replace spark plugs?

Answer: The replacement interval depends on the manufacturer’s recommendations and the specific engine and driving conditions. Usually, when you drive every 30,000 to 100,000 miles, you should change them.

Final Words

How was the discussion about projected vs. non-projected spark plugs? Throughout the debate, I have covered projection ideas, the benefits of both spark plugs, and other factors. I hope you can select the correct spark plug for your engine now.

Thanks for spending your time here. Feel free to share your thoughts on spark plugs.